Hexadrive Engineering first commercial digital twin

Efficient, Easy to Use and Scalable digital model of your electrical motor

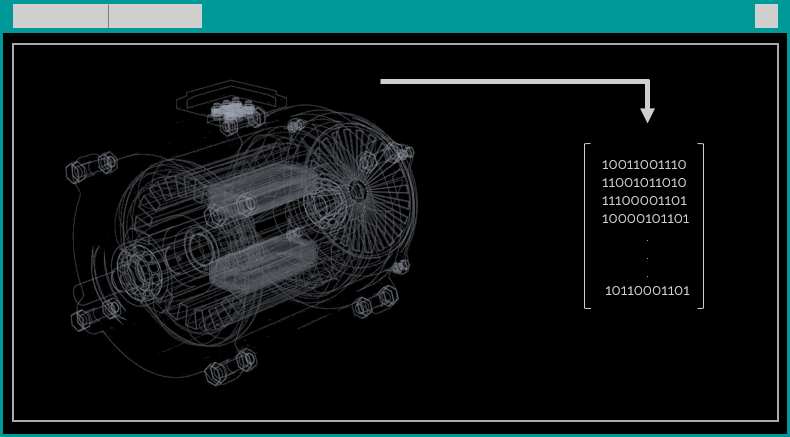

Take the machine design

and let our software do the rest

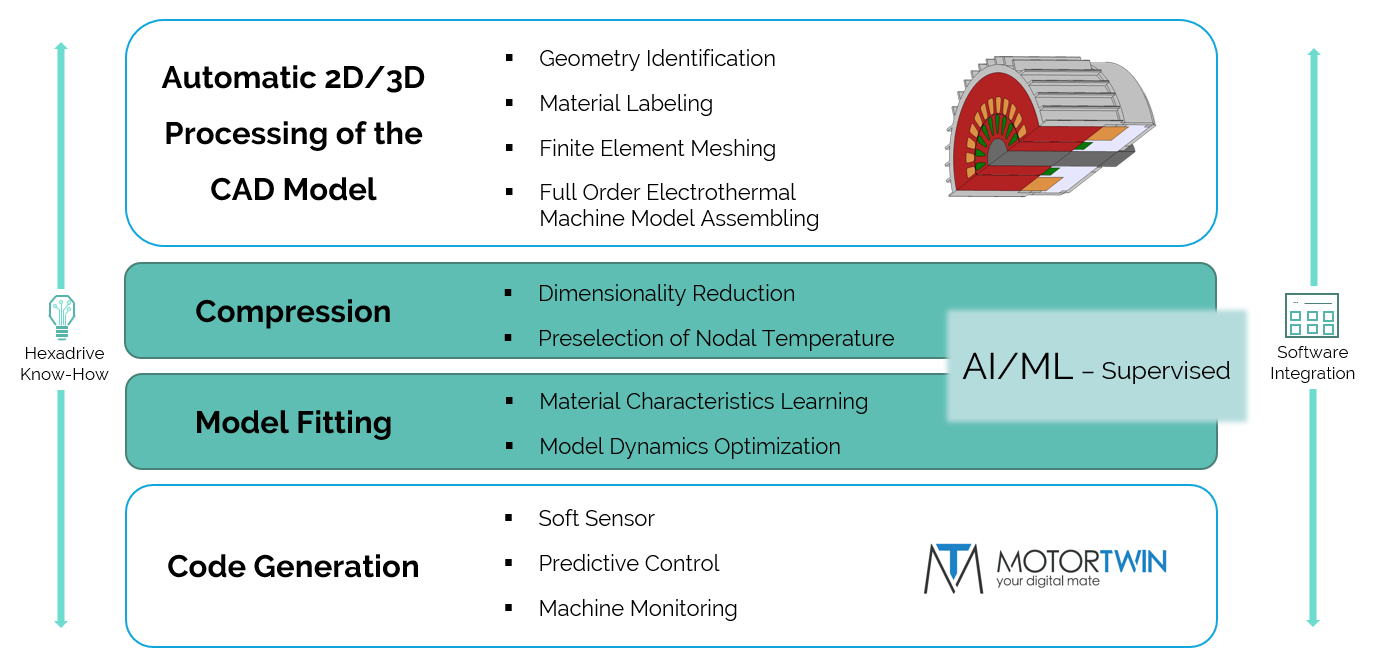

Our software has been designed to fully automatize the process of constructing a digital twin for an electrical machine.

We give the opportunity to our customer to directly upload the 2D/3D CAD file, while our software will take care of the pre-processing of the machine design before the construction of the digital model takes place.

A digital replica of the electrical machine ready to be used

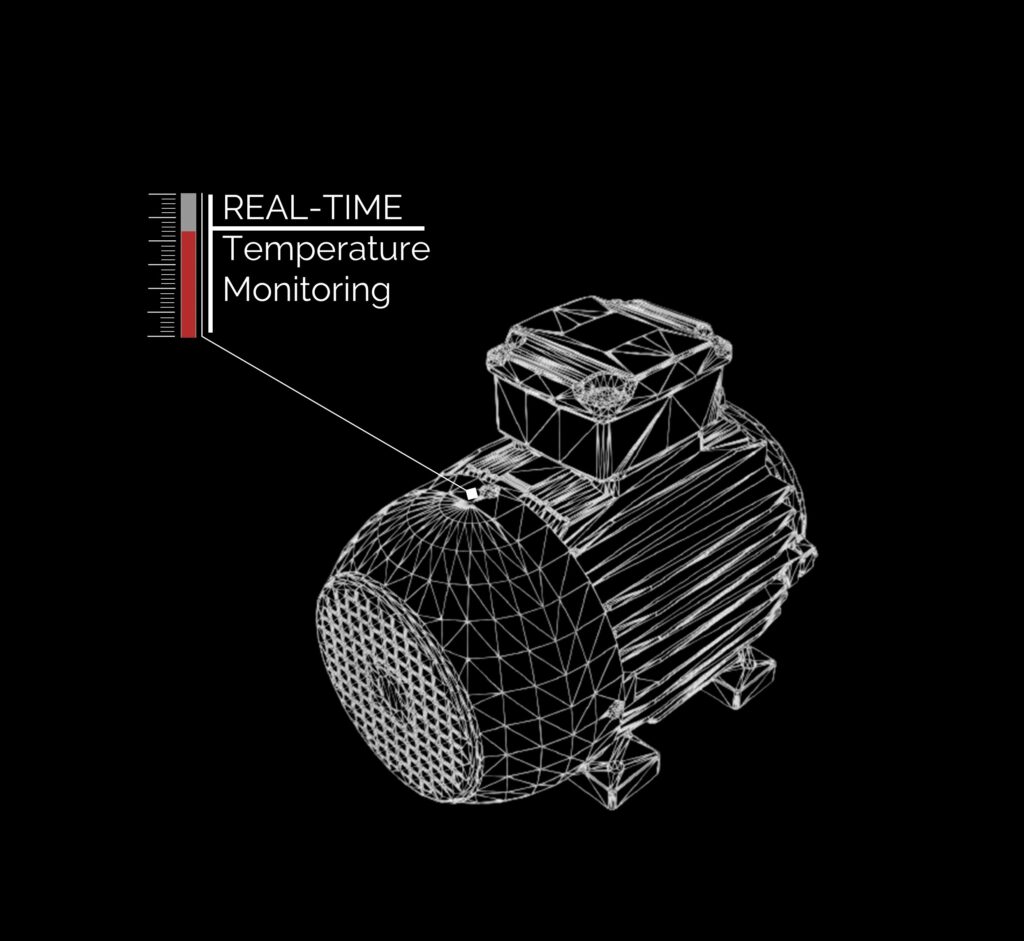

Imagine of taking a detailed X-Ray photo of your machine every sample time at a typical frequency of an industrial power converter. This is what MotorTwin is capable of.

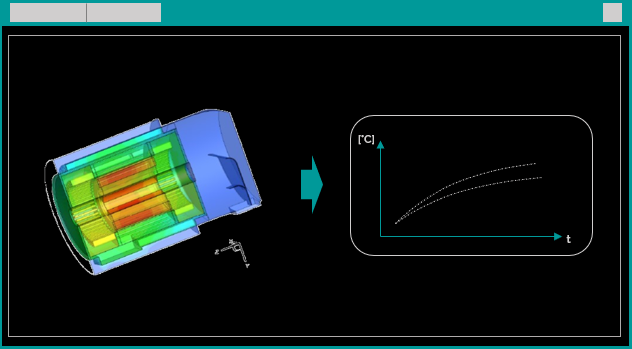

Simulate the electromagnetic and thermal dynamical behavior of your electrical machine with unprecedented accuracy and fast execution.

SOFTWARE FEATURES

MotorTwin has been developed with the goal of making the process seriously smooth for our customers. The CAD model of the machine can be directly uploaded into the software. It will automatically recognize and de-structure the most relevant geometrical parts for rendering an accurate digital copy, ready-to-use in a simulation environment and embedded hardware.

As an additional step, in order to obtain a high fidelity representation of the physical thermal machine’s behavior, the user can provide a few temperature measurement data, recorded at the housing’s surface. With the aid of machine learning algorithms, integrated into our software, the digital twin is calibrated to become the most accurate replica of the original system.

In the last model generation phase, ad-hoc developed algorithms compress and optimize the dimension of the mathematical system, delivering to the user:

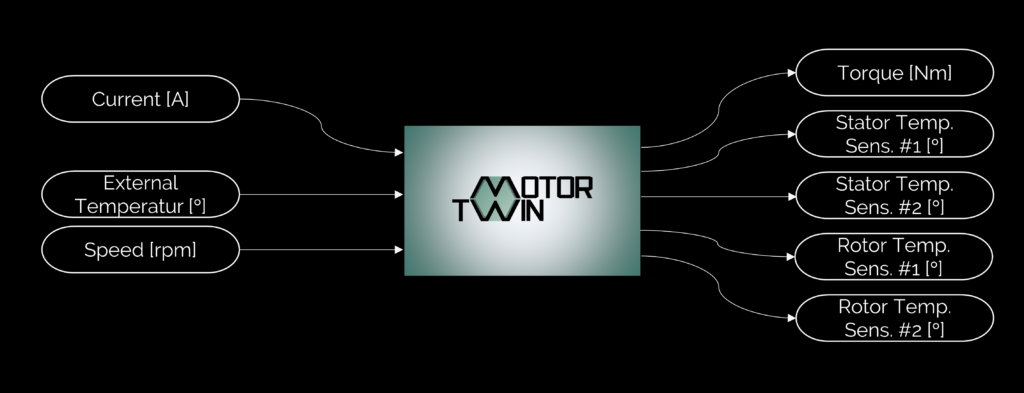

- A stationary electromagnetic model

- A dynamical lightweight thermal model

Both models are suited and ready to use in a simulation environment, such as Matlab-Simulink. The final version of the software will embed a code generator for further integrating the source code of the digital twin into target hardware.

HIGHLIGHTS

- Fully automated digital twin generation procedure

- Fast and reliable numerical model of your electrical machine

- Plug&Play in simulation environment for accurate electrical drive simulations

- C code generation for embedded application on specific hardware